- Portfolio

- 5 May 2020

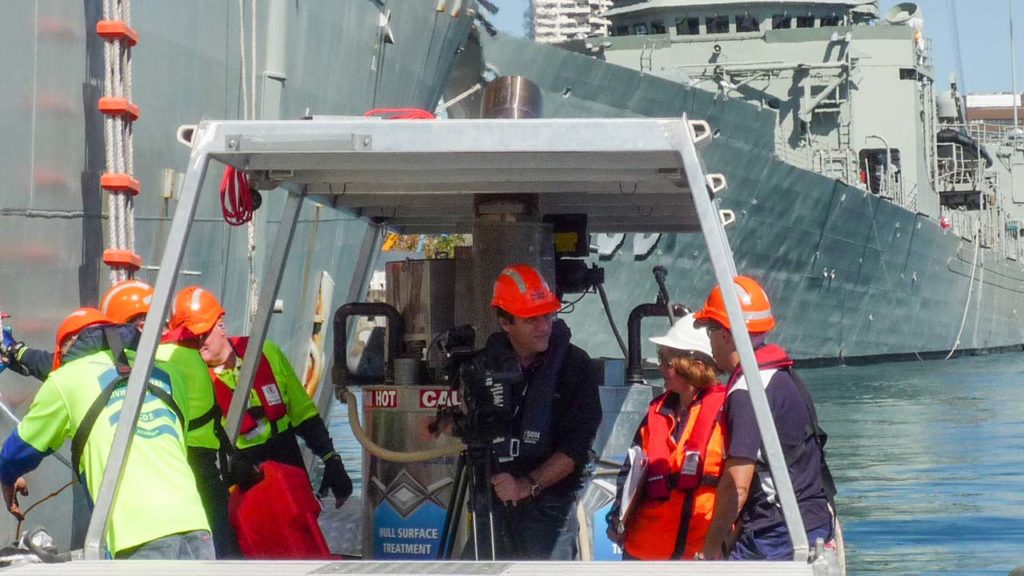

Before and after examples of our exclusive and patented HST Hull Cleaning service performed on various commercial vessels.

Hull Surface Treatment (HST) is an award winning ship hull cleaning technology underpinning an aggressive energy conservation program through reduced drag, increasing fuel efficiency and embracing environmental stewardship promoting reduced carbon emissions and a reduction to the risk of imported marine pests.

Hull Surface Treatment (HST) technology reduces a ship’s energy consumption. The application of a thermal shock to the underwater surface of a ship’s hull. The HST process does not remove or damage existing anti-fouling paints and is non-toxic.

HST technology uses ‘thermal shock’ to kill marine slime, algae and weed growth without its immediate removal. The dead growth is later washed from the hull by open sea and wave action when the ship has returned to sea.

Designed to be a proactive maintenance initiative, HST keeps the underwater surface clear of primary fouling eliminating the expensive impost and need to treat secondary and tertiary bio-fouling.

| Fouling Extent by Area of Wetted Hull | Friction + | Fuel + |

| 100% coverage of slime, occasional patches of weed | 20% | 12% |

| As above, plus 20% coverage of tube worm less than 6mm in height | 30% | 18% |

| As above, plus 20% coverage with barnacles less than 5mm in height | 40% | 24% |

| 80% Coverage with barnacles less than 5mm in height | 100% | 61% |

| 80% Coverage 10-15mm barnacles | 150% | 92% |

In 2010 Hull Surface Treatment (HST) was selected as a finalist at the Seatrade China Awards and Seatrade Asia Awards 2010. An impressive panel of judges agreed that HST ranked in the top five emerging technologies in Maritime Environmental Protection.

In 2009 Hull Surface Treatment (HST) was awarded 1st Prize for Environmental Innovation at the Lloyd’s List Asia Awards 2009. Again, the judging panel consisted of key shipping industry professionals.

In 2009 Hull Surface Treatment (HST) was a finalist and was runner-up at the Sustainable Shipping Awards London 2009 in the category of Ocean Environmental Protection resulting in further endorsement by an esteemed panel of judges.

In 2008 Hull Surface Treatment was recognised on five separate occasions when it was awarded 1st Prize by the Australian Business Awards 2008 in three separate categories including Innovation, Best Eco-Friendly Product and Best New Product. HST was awarded 1st Prize at the Integral Energy Illawarra Business Awards 2008 for Innovation and 1st Prize for Eco-Innovation in Business at the Future World Eco-Innovation in Business Awards.

HST is a passive system that does not remove layers of antifoul paint. Scrubbing and underwater water-blasting is aggressive and removes layers of expensive antifoul paint reducing its effectiveness and life expectancy. Hull scrubbing is no longer allowed in Australian waters, as is now the case in many countries, in order to prevent the introduction of foreign marine pests into the local aquaculture and also to prevent toxic plumes from antifoul paints discharging into the water. HST is the only alternative to hull cleanliness other than dry-docking.

HST uses hot seawater as its active ingredient to sterilize the hull. There are no additional chemicals used and the process does not disturb any of the anti foul paint so no toxins are released into the surrounding water. Although the growth is killed instantly it remains on the ships hull until the ship has sailed and is then polished off over the next two to three weeks using the accelerated hydraulic forces and wave action. No growth is disturbed so no foreign marine pests are introduced into the local environment. Consequently Hull Surface Treatment has been approved by the environmental authorities and can be applied safely in port and in many sheltered anchorages. Hull Surface Treatment is a very effective proven method of leaving ships hulls clean.

No, HST uses no chemicals but rather uses the local seawater. HST does not physically remove any growth. The treatment sterilizes the hull and kills the growth immediately. As the vessel sails over the ensuing two to three weeks the dead weed and algae is washed from the hull by accelerated hydraulic forces and wave action. No growth is disturbed so no foreign growth is introduced into the surrounding water. Consequently Hull Surface Treatment has been approved by environmental authorities and can be applied safely in port and in many sheltered anchorages.

The treatment to a Panamax sized vessel would normally take approximately two 8-10 hour days but can be completed in one day using two units simultaneously.

HST is a passive treatment applied to the hull gently. No antifoul paint is disturbed or damaged. Unlike scrubbing, the paint becomes exposed after treatment over a period of 2 – 3 weeks and the paint is then able to continue its job of resisting fouling. Due to the sterilizing action the spores of the growth are also killed slowing down the regrowth.

HST is a diver-less system and can be applied to the ships hull on the dock-side whilst alongside in most cases.

HST is a very environmentally friendly process. Not only does it not use chemicals or other contaminants it also reduces emissions. A clean hull means reduced CO2 emissions, big savings on fuel, decreased main engine wear and decreased dry-docking frequency.

The technology is specifically designed to operate whilst the vessel is in the water.

HST can be applied whilst the ship is carrying out cargo operations.

Yes. The Royal Australian Navy Science Organization has carried out extensive tests to the technology over a 10 month period and have scientifically proven that HST kills all the growth it treats and that growth is removed over the ensuing weeks.

HST discharges approximately 10 gallons of seawater every minute. Less than most harbor work boats discharge out of their engine cooling system. This is such a low flow that within 3 to 4 feet of the applicator the seawater is at normal ambient temperature. Independent tests have been carried out by an environmental company to ensure this was the case.

HST is not a coating, it is a treatment applied to existing coatings. HST is safe to use on any kind of underwater anti foul paint including the new generation fouling release silicon based coatings.

No, HST is designed to be a pre-emptive strike. The best way to prevent mature growth like barnacles is to stop them growing in the first place. HST is used in a maintenance program from dry-dock to dry-dock and keeps the hull clean. It can be applied to growth up to the level of immature tube worm. This also includes weed.

HST is designed to treat niche areas for bio-security purposes and can be applied to seachests and thruster tunnels.

HST requires sheltered water to operate. A sea state of less than 0.5 of a metre is required.

Hull Fouling starts from the moment a ship is placed back into the water after dry dock and continues for the life of the ship. A coating of slime and algae can cause a ship to have an increased hull resistance of 12% with in increase in fuel consumption of 7-10%. If a ship has 10mm to 30mm weed covering its laminar flow areas the resistance can be as much as 30% with a corresponding increase in fuel consumption of 23-26%.

HST has been proven to keep a ships hull clean if applied in a maintenance program from dry-dock to dry-dock. If this approach is applied HST guarantees that a ship will save approximately 4% – 6% of the propulsive fuel costs over the dry docking period.

HST is one of the few environmental technologies that saves considerably more money than it costs. Usually HST costs approximately 15% of the savings experienced with treatments.

HST can keep the hull of the ship clean for an extended period of time which has not been possible in the past. This is because HST is not abrasive and does not damage the coatings on the underwater section of the ship. Consequently it does not reduce the life expectancy of the paint. By passively keeping the hull clean on a regular basis it is possible to increase the time between dry-docking.

In all cases HST has not caused any damage to the underwater coatings of ships that have been treated by the technology. Anti foul paint companies have also suggested that the treatment may even help reactivate the paints.

An exhaustive R&D program undertaken by Commercial Diving Services Pty Ltd Australia over 5 years resulted in the commercialisation of an innovative energy and conservation technology designed to target hull fouling at its early stages. The issue of hull fouling is a critical consideration for shipowners. Fouling causes an increase in surface roughness and greater frictional resistance. A slime layer of only 1mm thickness can cause 15% loss in ship speed. The loss of vessel speed caused by fouling results in increased operating costs through higher fuel costs and the inability of vessels to meet schedules.

In the past 50 years Commercial Diving Services have observed the fouling process on many hundreds of ships around Australia. Ultimately, it was the banning of ‘in-water’ hull scrubbing that motivated their owners (Keith & Tim Johnson) to pursue a viable alternative. Research conducted by the Sea Systems Group within the United Kingdom’s Ministry of Defence and Navy Fleet HQ in 2007 has confirmed that hull-fouling reduces the effectiveness of a vessel with marked increases in fuel consumption and a reduction in top speed. Research conducted by the US Navy in 2002 proved that the speed loss of an aircraft carrier caused by heavy fouling was 1.5 knots, with a 40% increase in fuel consumed to maintain a speed of 20 knots.

Marine fouling has an immediate and potentially severe effect on ship performance. Any roughness on a ship hull that disrupts the laminar flow along the hull will produce drag. When a ship hull has been recently serviced, undergone complete sandblasting and painting, the hull will be as smooth as possible. Entering service, the hull will gradually roughen with time as a function of paint erosion and damage, fouling accumulation and corrosion. This roughness will increase drag and correspondingly propulsive fuel consumption. The magnitude of additional fuel use is quite variable, depending on the amount of fouling, the shape of the hull, and the speed at which the ship operates. Fuel penalties in the range of 10 to 25 percent have been observed on US Navy ships during sea trials. (www.biosecurity.govt.nz/about-us/our-publications/technical-papers)

Typically, there is a progression of attachment of marine organisms to a painted hull. The toxicant acts as a deterrent to the attachment of higher forms such as barnacles and tube worms, but will usually allow attachment of bio-films and algae to the hull within days or weeks of launching with fresh paint. As the anti-fouling paint ages and begins to lose effectiveness, calcareous forms will begin to appear, typically on sharp edges such as weld beads, bow thrusters, rope guards, sea chests and niche areas. This is then followed by a more general infestation, spreading beyond edges onto the flats of the ship hull.

The US Navy with a fleet of 300 ships… acknowledges (2009) that colonised barnacles and bio-films on the hull of their ships’ translates’ into roughly $US500 million annually in extra maintenance and fuel costs. HST is a clean hull technology which offers significant return on investment and will enable military and commercial fleets to operate worldwide without being constrained by local, national or international environmental laws and regulations.

The most effective anti-fouling paint (TBT) known to the shipping industry has been banned by the IMO and can no longer be used in most ports around the world. The most effective means of removing fouling from the underwater surface of ships hulls (hull scrubbing) whilst in port or harbour has also been banned by most member nations. Currently, HST is the only successful anti-fouling technology that does not pose a threat to the environment and in fact, reduces the bio-security risk presented by international shipping.

Hull Surface Treatment (HST) technology kills marine bio-film, slime, algae and weed attached to the underwater surface of commercial and military shipping without compromising the marine ecosystem. HST is a non-abrasive system which causes no damage to the anti-fouling paint system. HST uses an innovative delivery system of ‘low flow’ hot sea water as its active ingredient, encapsulated in a thermal applicator which moves over the underwater surface of the ship’s hull, delivering a thermal shock… killing all bio-fouling at its primary stage of development.

HST is not designed or intended to be applied to hard/tertiary fouling on the laminar sides or flat bottom of the vessel. Barnacle growth is not suitable for HST application. The best way to stop barnacle growth from colonising is don’t let them settle and colonise on the hull in the first place, through the use of HST maintenance.

HST is designed to be used in a proactive and coordinated maintenance program, effectively eliminating infant marine growth (fouling) before it is able to develop and have a significant and detrimental effect on the vessels performance and fuel consumption… a pre-emptive strike as it were… terminating the spore and slime before it has a chance to develop into a major threat to the vessels performance and energy consumption.

HST is a diver-less and portable technology easily operated by a two man team from a small tender vessel or form part of an on-board crew operated system. Subject to the effectiveness of the anti-fouling paint system, the vessels global movements and prevailing climate, HST may only need to be applied twice per annum.

The HST system does not remove live organisms into the local marine ecosystems of our Ports and Harbours… but rather kills all marine slime, bio-film and algal growth and leaves it attached to the ship’s hull. Once the ship leaves Port, the dead marine growth is removed by the accelerated hydraulic force of ocean and wave action over ensuing weeks effectively neutralising any risk of biological invasion from marine pests forming part of the slime, algal and weed fouling. HST does not perform physically destructive actions in the aquatic environment.

HST provides a significant part of the solution to the anti-fouling quest… both in terms of its environmental and commercial contribution.

HST is the environmental solution to a complex and toxic history of applying and maintaining anti-fouling paints to the under- water surface of large ships. An adjunct to the new generation of anti-fouling paints… HST will extend periods between dry-dock, promote fuel conservation, reduce green-house gas emissions and have a significant impact on Imported Marine Pests.

Commercial shipping is responsible for approximately 5% of global oil consumption estimated to be worth $US30 billion. In 2007 the annual carbon dioxide emissions from world shipping reached 1.3 billion tons.

A survey of 100 ships undertaken by Propulsion Dynamics suggests that the average fouling resistance for a Commercial ship is 30% if no special attention has been paid to anti-fouling. Their experience suggests that at least 10% may be saved on average fuel costs and they recommend that a ship’s hull should be cleaned before the slimy layer of bacteria and algae turned into a layer of seaweed. These findings are consistent with both the US and UK Navy’s.

For a ship that consumes 100 ton of fuel per day, at least 10 tons per day may be saved. This represents a value of approximately $US 5,000.00 per day or approximately $US 1,330,000 per year, assuming that the vessel sails for 266 days per year and fuel is $500 per ton.

HST is designed to stop/reduce the process of primary fouling before it elevates to secondary and tertiary levels. It is important to note that HST is not designed to be applied in open water anchorage or average swell exceeding 50cm. HST enables regular and preventative treatments and in so doing… saves fuel consumption, substantially reducing the carbon footprint attributable to shipping and greatly enhancing the anti-fouling paint systems applied to the world’s ships.

HST technology has been patented around the world.

Commercial Diving Services ® PTY LTD | CDS ® | SCD ® | ©